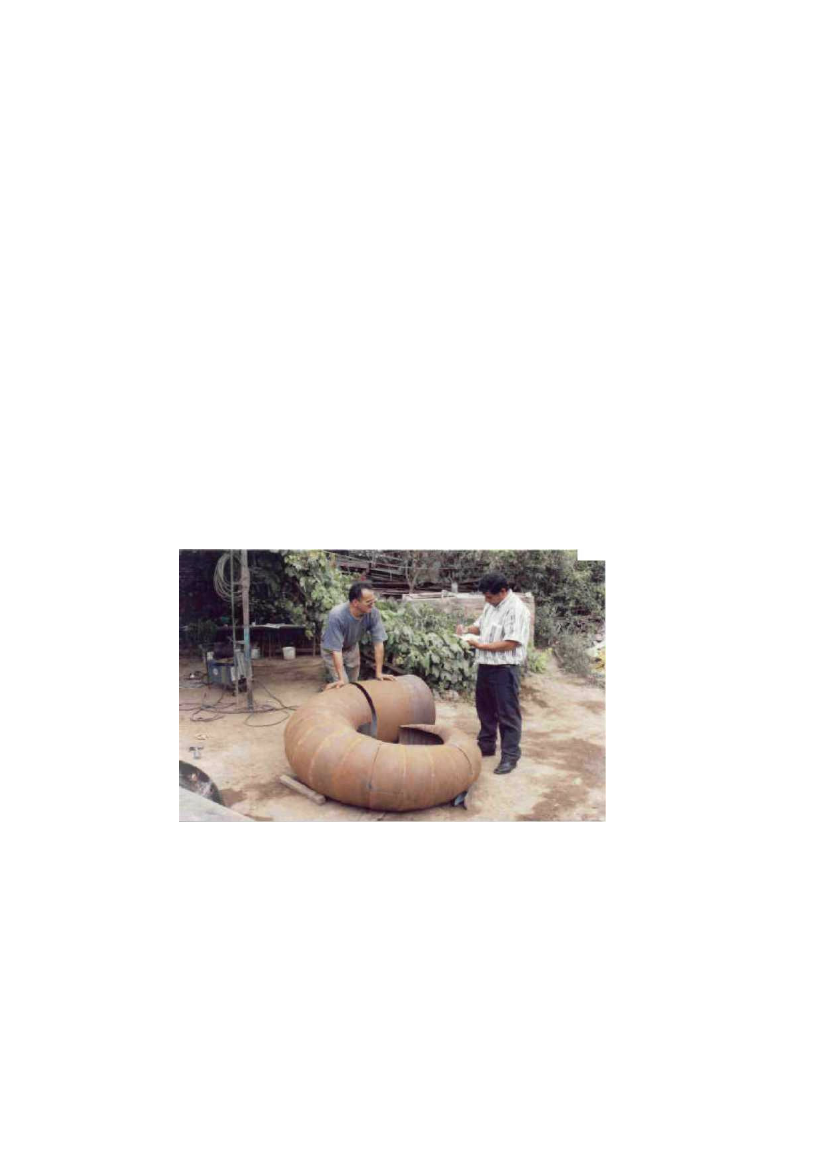

• Welding. The joint between the segments of both the spiral and the

suction tube is arc-welded, given the widespread prevalence of this

technique in small-scale workshops. The welding process begins by

securing the segments or parts with spot welds, checking the

dimensions and that they are truly square, before finally bead-welding

them together, attempting to keep any buckling caused by the welding

process itself to a minimum. Such buckling occurs as a result of

localised overheating, making it advisable to weld in sections, allowing

other parts to cool down on an alternate basis. (Fig. 12 and 13)

The electrodes used for spot welding and joining the sections are

penetration electrodes (E6011), and E6013 electrodes for finishing. 1/8"

E6011 and 3/32" E6013 electrodes should preferably be used for the

1/8" sheeting, although this depends on the welding equipment and the

skill of the welder.

Figure 12: Welding of the spiral segments